What is MTBF?

MTBF stands for Mean Time Between Failures — a reliability metric that estimates the average time a product operates before a failure occurs under normal conditions.

In simple terms, it’s an indicator of how reliable a power supply unit (PSU) is expected to be over its lifetime.

How MTBF is Calculated

MTBF values are typically calculated using reliability prediction models such as MIL-HDBK-217F or Telcordia SR-332. These models consider component failure rates, environmental factors, and test conditions like operating temperature, input voltage, and load levels.

However, real-world conditions rarely match lab environments.

For example, an MTBF rating of 100,000 hours doesn’t mean the PSU will run continuously for 11 years.

Instead, it means that if 1,000 identical units operate simultaneously, statistically one unit might fail every 100 hours. It’s a probability metric, not a guaranteed lifespan.

Why It Matters for PSUs

MTBF helps engineers and users estimate a power supply’s reliability over time. A higher MTBF generally suggests better design, higher-quality components, and strong thermal management — all of which contribute to consistent performance and reduced failure risk.

MTBF vs. Actual Lifespan

While MTBF provides insight into reliability, it does not directly reflect real-world lifespan.

Manufacturers determine MTBF under controlled test conditions, but actual systems may face temperature fluctuations, voltage spikes, dust accumulation, or variable loads that shorten lifespan.

In practice, environmental stress often plays a bigger role than theoretical MTBF.

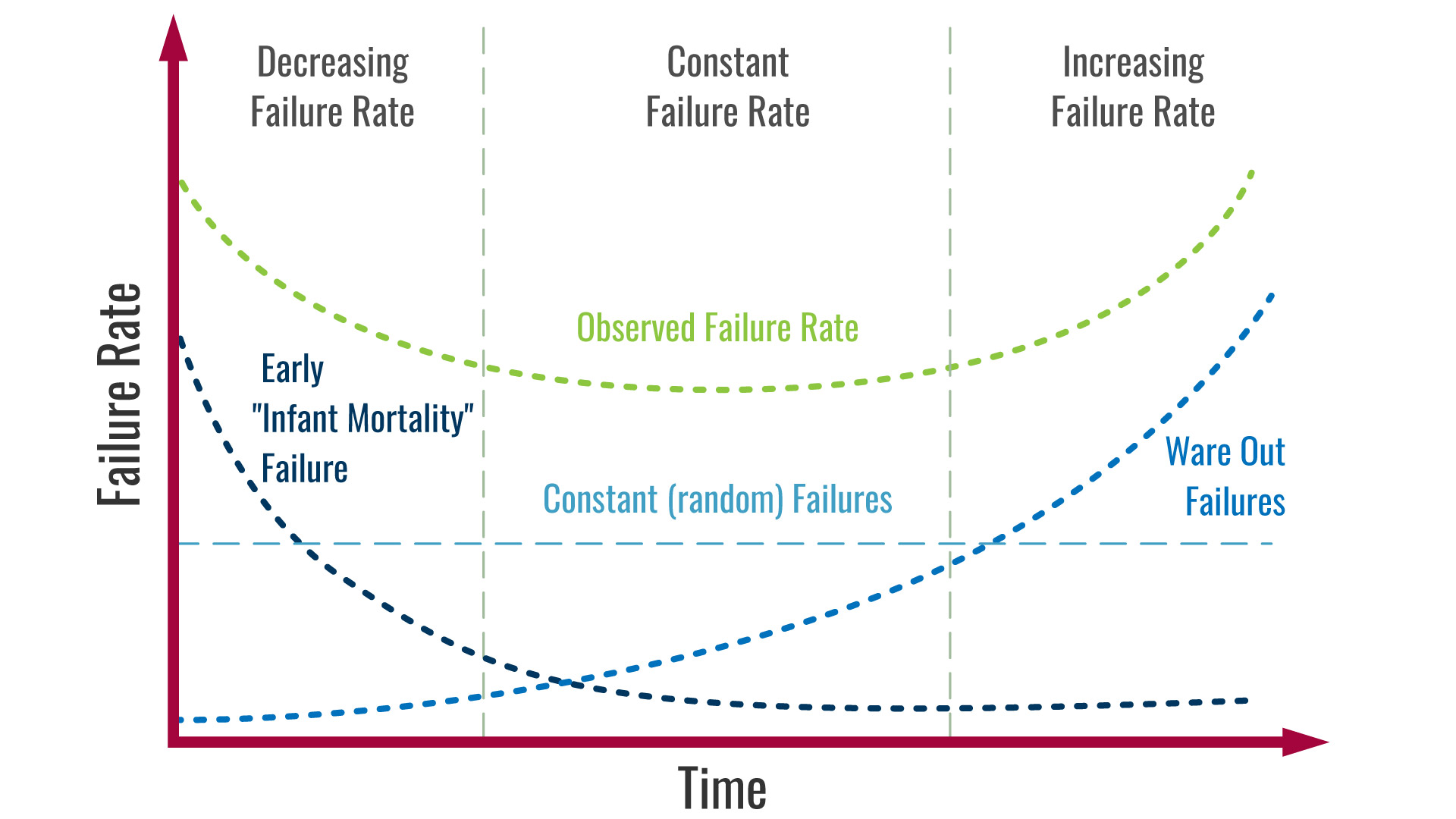

Early Failure:

This initial phase has a higher failure rate at the beginning, which drops quickly as early defects or weak components are eliminated.

Normal Operating Life (Steady State):

During this phase, the failure rate remains relatively constant throughout the product’s useful life. Reliability is typically expressed using FITs (Failures in Time) or as MTBF (Mean Time Between Failures) measured in hours.

Wear-Out Failure:

At this stage, natural aging and material degradation begin to dominate, causing the failure rate to rise rapidly. A product’s effective lifetime is generally defined as the period from initial production up to the onset of this wear-out phase.

Key Takeaway

Think of MTBF as a comparison tool, not a promise of longevity.

It’s most useful when comparing models or brands — especially alongside other durability indicators such as capacitor lifetime, component derating, and thermal performance. Together, these factors give a clearer picture of how long and how reliably a PSU will perform in real use.